1.1 Wood Plastic Composite Definition:

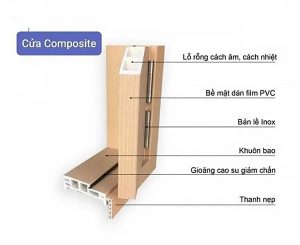

Wood plastic composite is a type of material created from a composition of wood and plastic, consisting of 70% finely ground wood powder sourced from forests and 30% virgin PVC resin along with additives. These components, once synthesized, are subjected to compression molding and injection molding using existing molds. These molds vary in wood grain patterns, specifications, etc., contributing to the creation of diverse and visually appealing plastic wood floors that effectively meet the needs of consumers.

The most significant use of plastic wood is in the form of wood plastic composite material, extensively employed in the production of household furniture and particleboard for office furniture. Both of these materials are notoriously challenging in terms of durability, especially susceptible to damage in humid environments or when exposed to water, resulting in a very short lifespan for indoor and outdoor furniture.

Recognizing this vulnerability, scientists have applied composite technology to industrial wood production, creating composite wood materials with a primary composition of finely ground natural wood powder and formed plastic particles. This type of material demonstrates excellent water resistance and stable usage, ultimately providing high durability.

2. Advantages of Alux Composite Doors:

- Absolute Water Resistance:

- This is a remarkable advantage that allows this material to be used for outdoor projects, even in high humidity areas. Many bathrooms and sanitary facilities have also adopted composite wood doors.

- No Warping or Shrinking:

- This is a notable feature of this product line. Thanks to this characteristic, structures maintain their beauty with the highest possible lifespan.

- Termite and Mold Resistance:

- Processed through modern procedures, Wood Plastic Composite material has a high resistance to termites and mold.

- Fire Resistance and Excellent Insulation:

- Offers good resistance against fire and provides effective insulation.

- High Load-Bearing Capacity:

- Overcomes the drawback of industrial wood; Wood Plastic Composite can withstand substantial forces.

- Lightweight:

- With this property, the product is widely used in construction projects to reduce the overall load on structures.

- Easy to Carve and Print on the Surface:

- Facilitates easy carving and printing on the surface, allowing for intricate designs.

- Easy Shaping:

- Using Wood Plastic Composite material, you can craft many details that are difficult to achieve with traditional wood.

- Reasonable Cost, Cost-Effective:

- The use of this material is more cost-effective than pure plastic, as plastic involves the additional time and cost of mold creation, which is not required for Wood Plastic Composite.

3. Machinery for Composite Door

Reliable Composite Door Manufacturing Plant

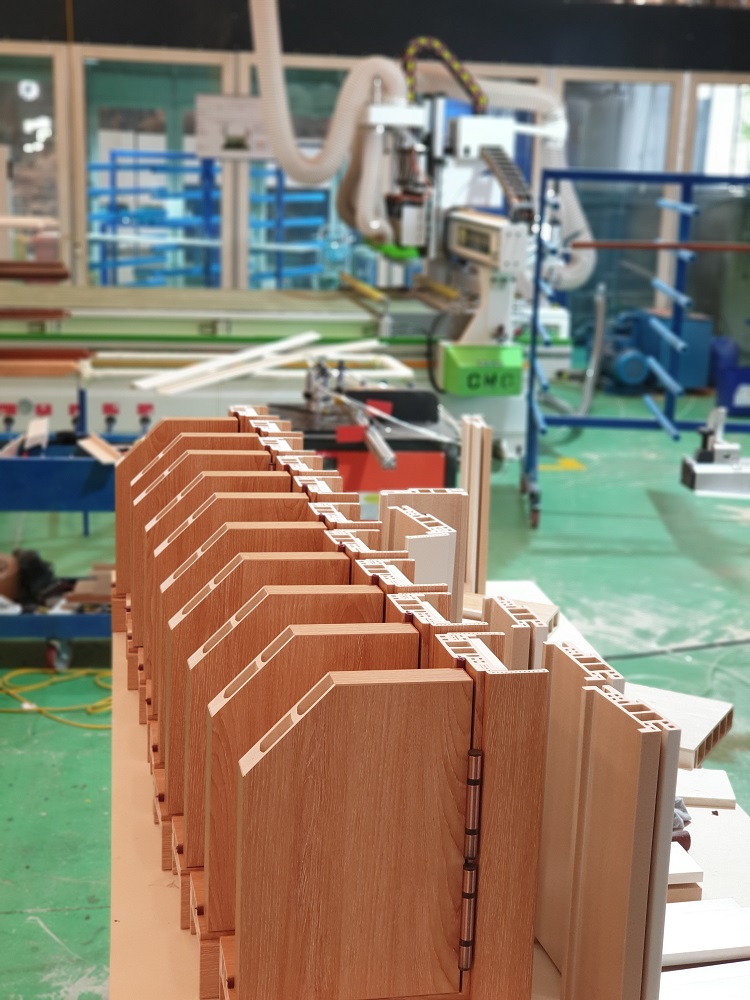

Alux stands as a reputable manufacturer of composite doors and a trusted provider of door installation services across the entire country. We consistently optimize our production processes to deliver the best products to our customers.

Leading in Trends and Quality

- Our collection of Composite Doors at Alux is continually refreshed with the most beautiful designs, staying in line with current market trends.

- Beyond ensuring aesthetic appeal, Alux is committed to maintaining the quality of our manufactured doors, meeting the standards set by regulations.

Standardized Production Process

- Each type of door undergoes specific production standards. Composite doors are manufactured using advanced technological processes, and the quality of raw materials is scrutinized to ensure consistency across all production steps.

Diligent and Prompt Execution of Construction and Installation

- Once the composite doors are completed in our manufacturing plant, the installation process is scheduled promptly with our customers, adhering to the standardized 7-step procedure.

Extensive Showroom Network and Professional Staff

- Alux boasts a widespread network of showrooms across southern provinces with multiple branches. Our production facilities and workshops are strategically located to guarantee swift production and installation progress.

- Our team of dedicated staff and advisors at Alux are always enthusiastic about assisting and supporting customers at every stage, whether it’s in design, model creation, construction, or door installation.

Current Offerings at Alux Composite Door Manufacturing Plant

- Alux currently provides a diverse range of door models with highly attractive pricing and significant promotional offers.

5. Machinery for Composite Door Production

In addition to the human factor, the role of various machines in the production of composite doors is crucial. Below are some fundamental types of machinery utilized in the processing of plastic wood doors:

——————————————–

ALUMAX VIETNAM JOINT STOCK COMPANY

Headquater: No.70 Nam Duong str, Thuong Thanh ward, Long Bien distric, Hanoi city.

Hotline: 0961 362 362

Website: www.alux.com.vn

Tiếng Việt

Tiếng Việt