Today, Alumax Vietnam would like to share with our valued customers about what composite doors are, their structure, and the applications of composite plastic doors. Composite wood doors are a type of high-quality imitation wood door made from wood-plastic composite (WPC). Wood-plastic, also known as Composite Plastic, is a type of synthetic material reinforced with plastic. It is a composite material formed from wood powder and plastic, along with some cellulose-based additives. Currently, composite wood is applied in the furniture industry, especially for main doors, interior doors, or bathroom doors.

A composite wood door is designed to look like a wooden door, with attractive wood grain patterns. However, thanks to the materials used, it does not fade and requires minimal maintenance, only needing to be wiped with a damp cloth if dirty.

Advantages of composite wood doors:

- Low maintenance.

- Aesthetic appeal.

- Sturdy and strong, able to withstand impacts.

Disadvantages:

- Due to being made from various materials, composite materials lack recycling and reuse capabilities compared to conventional plastics.

- Not environmentally friendly and may pose health risks.”

Please note that the translation is for informational purposes and may require further refinement based on the context and specific terminology used in your target audience.

1.What is Composite Wood Plastic Door?

Composite wood plastic is one of the new material models researched by American scientists for manufacturing. Based on main components derived from nature such as plantation wood combined with PVC, they successfully created the first models around the early years of the 21st century.

Recognizing the outstanding features and vast development potential of this composite wood material, European countries have applied it to the construction industry, developing it into a popular commercial product. However, the significant success was achieved after research in the United States, building upon advanced European technology. Currently, China is the world’s largest producer of composite wood.

Composite wood doors, made from Wood Plastic Composite (WPC), a type of natural fiber-reinforced plastic, are visually designed to resemble natural wood with wood grain patterns.

Composite wood doors are created from PVC and natural wood powder, along with cellulose-based additives, pressed into sheets with water-resistant properties of plastic and the rigidity of wood. As a result, composite wood doors are heavy, similar to natural wood, and do not require maintenance or fade during use, making them highly popular. This type of composite wood door is, in fact, a high-quality imitation wood door widely used in interior design, such as for main doors, interior doors, and bathroom doors.

Advantages of Composite Wood Doors:

- Low maintenance.

- Aesthetic appeal.

- Sturdy and strong – able to withstand impacts.

Disadvantages:

- Due to various materials, composite materials lack recyclability compared to conventional plastics.

- Not environmentally friendly and may pose health risks.

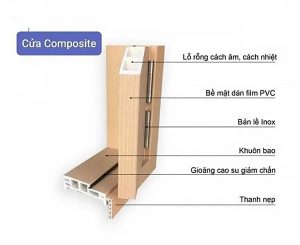

2.Structure of Composite Doors

- Door Leaf (38mm): Wood plastic composite material is pressed into a shaped profile. The surface is covered with PVC film imitating wood grain in the specified color.

- Frame (43mm): Wood plastic composite material is pressed into a shaped profile. The surface is covered with PVC film imitating wood grain in the specified color, with rubber gaskets for shock absorption.

- Trim with dimensions 12×55: Wood plastic composite material is pressed into a shaped profile. The surface is covered with PVC film imitating wood grain in the specified color.

- Homogeneous structure: The homogeneous structure is wood plastic composite material. The exterior is covered with PVC film using heat and vacuum technology (no glue is used).

Composite wood doors are coated with a premium PVC film, providing a simulated natural wood grain pattern and uniform color. The connection of the frame and trim of composite wood doors uses a smart strip directly inserted into the frame, ensuring a high aesthetic value. If repairs are needed, removing the strip is simple and does not affect the door assembly.

The PVC film surface has good scratch resistance and chemical resistance. Austdoor composite doors have been tested by the General Department of Quality Measurement and determined not to be affected by chemicals (NaOH 40%, NaCl 10%, H2SO4 40%, and HNO3).

3.Classification of Composite Wood Doors

3.1. Composite Panel Doors

Composite panel doors are made from fine plywood combined with water-resistant PVC. The product is pressed into solid PVC shapes to achieve 100% water resistance, making it suitable for use as interior doors, bedroom doors, hotel rooms, bathrooms, and auxiliary rooms. Additionally, composite doors have properties that resist termites and chemicals, increasing their durability. The doors also feature a rubber gasket running along the frame for sound insulation and shock reduction.

3.2. Composite Doors with Wooden Frames

Composite doors with wooden frames are made from a frame of jointed wooden beams, with honeycomb paper filling the gaps and two layers of composite plastic pressed on the outside. This product also has water resistance, termite resistance, and resistance to harmful chemicals.

4.Key Features of Composite Wood Doors

As a newer door type, composite wood doors have almost overcome all the disadvantages of previous plastic door types and wooden doors. They have established a unique position in the market, with widespread use in both large and small projects, from major cities to provinces and rural areas.

Composite wood doors are particularly suitable for high-rise buildings and villas because they can overcome the shortcomings of natural wood while leveraging the advantages of composite materials. The product’s features include:

- Weather Resistance:

- Vietnam, with its tropical monsoon climate, experiences various weather conditions from warm sunshine to heavy rain. This unusual weather is a significant challenge for wooden interior products, especially doors. If a house chooses a wooden door as the main entrance, that door will bear the brunt of all weather conditions. The question arises: Can a wooden door withstand the humidity after heavy rain, or endure the scorching sun in summer?

- This question has caused much hesitation among customers in choosing a suitable door for their homes. Besides wooden doors, there is another alternative that can resist the harsh weather, namely steel doors. However, simple steel doors lack aesthetics and are even more expensive.

- Composite wood doors emerged as a solution to this longstanding challenge for contractors and designers involved in installation. It is an excellent solution that covers all bases.

- While natural wood is hydrophobic, composite wood overcomes this issue because it is quite water-resistant and operates well in high humidity environments. Produced according to ISO standards with the protection of a PVC layer on the surface, composite wood doors can withstand the impact of sunlight, water, and humidity without warping or swelling. This advantage makes composite wood doors suitable for various positions such as room doors, main doors, toilet doors, and windows. Moreover, the cost of composite doors is reasonable, and their aesthetic appeal is extremely attractive.

- Longevity and Durability:

- Made from wood powder combined with natural resin and cellulose fiber additives, composite wood doors are naturally evaluated as having high longevity, good load-bearing capacity, and positive feedback from many customers regarding durability and smooth operation. During use, the doors do not deform or get damaged.

- The structure of plastic particles covering wood particles gives this composite door type the rigidity of wood and the flexibility of plastic. With a leaf thickness of 40mm, the door frame is nearly equivalent to industrial wood doors and much larger than ABS plastic doors. This ensures that the door can adapt to various types of wood door accessories, including electronic locks.

- High Safety:

- When it comes to composite doors, people immediately think of a door type with water resistance, moisture resistance, high durability, and, seemingly overlooked, an important feature: safety.

- First and foremost, in terms of raw material composition, a crucial factor is that composite wood doors are produced from wood powder and PVC resin, both of which are virgin materials. All these materials are safe for humans and do not use adhesive glue or harmful additives.

- Second, its slow-burning, non-flammable nature and limited ability to spread fires are crucial advantages rarely mentioned for composite wood doors.

5.Applications of Composite Wood Doors

Composite wood doors, with their outstanding advantages, have high applicability in daily life. With their superior features, various models of composite wood doors are becoming the choice of many modern families for installing main doors, interior doors, bedroom doors, living room doors, bathroom doors, etc.

Composite wood doors are meticulously designed with a variety of models, and CNC grooves on the doors are intricately carved. A special feature of the door models is that they can be freely designed according to customer requirements without being constrained by existing patterns.

In terms of color, composite wood doors can

——————————————–

ALUMAX VIETNAM JOINT STOCK COMPANY

Headquater: No.70 Nam Duong str, Thuong Thanh ward, Long Bien distric, Hanoi city.

Hotline: 0961 362 362

Website: www.alux.com.vn

Tiếng Việt

Tiếng Việt